10:45 PM Nitrogen removal from natural gas |

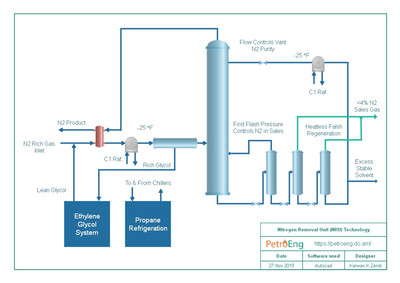

At the gas plant, initial steps remove any remaining particulate matter and further reduce the water-vapor content of the incoming gas. Then, focus turns to the separation of hydrocarbons and fluids to yield pipelinequality dry natural gas. Whether naturally occurring in gas reservoirs or resulting from injection into the gas cap for pressure maintenance, nitrogen is frequently present in natural gas at levels that decrease its quality and restrict its marketability. At the gas plant, initial steps remove any remaining particulate matter and further reduce the water-vapor content of the incoming gas. Then, focus turns to the separation of hydrocarbons and fluids to yield pipelinequality dry natural gas. Whether naturally occurring in gas reservoirs or resulting from injection into the gas cap for pressure maintenance, nitrogen is frequently present in natural gas at levels that decrease its quality and restrict its marketability.Nitrogen can reduce the heating value of natural gas (because nitrogen does not burn). After the removal of carbon dioxide and hydrogen sulfide, the processed natural gas goes through a low-temperature distillation process to liquefy and separate the nitrogen. The collective removal of carbon dioxide, hydrogen sulfide, and nitrogen is called upgrading, because the natural gas is made cleaner and will consequently burn hotter. The need for nitrogen removalIf the plant feed gas contains nitrogen, this must be removed to limit the nitrogen content of the produced LNG to no more than 1 – 2%. Traditionally, the maximum nitrogen content of LNG has been dictated by fuel quality limitations. However, with increasing trade in LNG import, storage and export, significant quantities of LNG can be held in storage, particularly in the US. In this event, it is not unusual for a limit of 1% nitrogen in LNG to be imposed to avoid any possibility of ‘auto-stratification’ in the LNG storage tanks, which can be a precursor to tank ‘rollover’.For relatively low feed gas nitrogen levels of approximately 1 – 2 mol%, Nitrogen removal can be achieved by flashing of the LNG, as nitrogen accumulates in flash gas. For nitrogen levels greater than approximately 2 mol%, a fractionation column is normally required to strip nitrogen from the LNG. This column typically incorporates a reboiler to produce stripping vapour, which ensures the nitrogen level in the LNG is less than 1 mol%. A stripping column is effective in removing nitrogen from the LNG but significant quantities of methane are revaporised and pass with the overhead nitrogen. This column overhead stream is normally compressed and used as fuel gas for generation of power, or to drive compression machinery in the liquefaction plant. Revaporising LNG to produce fuel gas at ambient temperature is clearly inefficient. |

|

|

| Total comments: 0 | |